Today I Learned – Carbon Sequestration

Carbon is the most common GHG (greenhouse gas) produced in both natural ecological processes and in abundance by human being’s through various industries and technologies. The excess of GHG has an adverse effect on climate.

The overview of climate change is already familiar to us: excess carbon production as a greenhouse gas leads to a rise in global climate temperature which in turn leads to climate events and patterns that can cause great suffering and cost.

Many countries, and once again the United States, are participating in The Paris Agreement to tackle the mitigation of climate change and global warming through science, technology and policy. The current President of the United States’ stated goal is a 50-52% reduction of emission by 2030 with net zero emissions by 2050. This is certainly a bold goal for climate mitigation and sustainability.

As a renewable resource-based industry, we must embrace the science and continually proclaim the contribution of our business practices to the greater good of sustainability goals as tied to the supply chain.

As an industry, we earn it by every pallet and pound of wood that is recycled and re-used, and contributes to a reduction in greenhouse gases through continued carbon sequestration.

In today’s Nature’s Packaging discussion, we take a look at carbon sequestration and how wood and pallets are capable of net positive impacts on sustainability goals for the industries serviced by the wooden pallet and container industry.

Carbon Sequestration

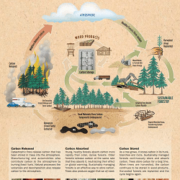

The chemical, physical, and biological processes of the earth capture carbon from the earth’s atmosphere. In carbon sequestration, carbon dioxide in the atmosphere is absorbed by trees, grasses, and other plants via photosynthesis and stored as carbon in biomass (the trunks, branches, foliage, and roots) and soils.

Trees feed on the carbon dioxide in the atmosphere. A truly efficient carbon capture system created by nature. As a renewable resource, forest management and tree planting are a core strategy to reduce carbon emissions and combat deforestation.

As long as that wood exists in some form, the carbon stays trapped inside. Thus, wood-based building materials keep the carbon trapped. Mass timber technologies is a great example here.

As far as wood pallets are concerned, the National Wood & Pallet Container Association in conjunction with the USFS-Forest Products Lab has developed a cradle-to-grave Life-Cycle Assessment that speaks directly to emissions and carbon capture. The Environmental Product Declaration is a great resource to share with customers and those that manage sustainability initiatives in their organizations.

Another great tool is the NP carbon calculator, which is available right here on the Nature’s Packaging website. The carbon calculator is an easy-to-use, easy-to-understand tool that allows you to demonstrate to customers, employees, and others just how effective pallet recycling is for reducing carbon emissions.

The calculator will show not only the metric tons of carbon dioxide emissions that are saved per month, it also frames that calculation into how many equivalent cars are taken “off the road” per month. “This estimation is based on the EPA Waste Reduction Model (WARM) for “dimensional lumber”. It is derived by taking the difference between the net CO2 emissions produced by land-filling and the net CO2 emissions produced by recycling dimensional lumber”. *from the Nature’s Packaging carbon calculator tool

The WARM Model

The Waste Reduction Model (WARM) calculates and sums greenhouse gas emissions, energy savings and economic impacts of baseline and alternative waste management practices, including source reduction, recycling, combustion, composting, anaerobic digestion and land-filling. The model calculates emissions, energy units and economic factors across a wide range of material types commonly found in municipal solid waste in the following categories:

- Metric tons of carbon dioxide equivalent (MTCO2E),

- Energy units (million British Thermal Unit – BTU),

- Labor hours,

- Wages ($), and

- Taxes ($). *Basic Information about WARM

The EPA’s Waste Reduction Model (WARM) recognizes 54 material types. In situations where a material isn’t directly recognized, it is acceptable to use a proxy. To be considered a suitable proxy, a material should be similar in processes related to:

- How materials are acquired

- How the product is manufactured

- How the materials are collected at the end of their lifecycle

- What materials and processes are offset when the primary material is recycled

A proxy is rated as Acceptable, Good, or Very Good. In the case of wood pallets, they are rated as Very Good based on the components of a pallet being dimensional lumber.

The WARM and proxy information for dimensional lumber are utilized correctly in the carbon calculator tool on the Nature’s Packaging website, so feel confident you are using an important tool to help your customers.

Climate change mitigation and sustainability goals are fast becoming center stage in government and corporate policy initiatives around the world. The wooden pallet and container industry will continue to do our part through beneficial business practices and helping other industries achieve their recycling goals now and into the future.