The Forests of Gabon

Forest products play a crucial role in many countries and their available resources. In the African nation of Gabon, forest products are pointing the way forward in a country that finds itself winding down its oil production and needing to find alternate sources of investment and resources.

NP readers know that we at Nature’s Packaging support sustainably sourced wood from sustainably managed forests. Wood is a multifaceted medium that is utilized in everything from buildings (mass timber), to furniture, to the wooden pallet and crate.

The government of this small African nation understand that their forests are an opportunity to open new markets and create jobs for its citizens.

Join Nature’s Packaging as we take look how the country is working to balance its need for new revenue and to sustainably manage its abundant forest land.

The Eden of Africa

Known as the “Eden of Africa”, the nation of Gabon is rich with forestland (it covers about 90% of the country) and has one of the largest elephant herds in the world. For decades though, it has relied on its oil production to fuel the economy. The oil producing sector has shielded the country’s economy from the larger fluctuations in Africa’s overall economic woes at various times in history.

However, as their calculated oil reserves begin to dwindle the government has turned to its forests to make the transition from oil as its main economic driver to a diversity of forest products. The challenge is to balance the need to extract these resources with the preservation of its precious forests and the climate change conditions happening around the world.

To maintain that balance, Gabonese officials have implemented strict rules regarding logging that keeps the majority trees standing and developing into old-growth timber. In fact, those strict rules limit logging to two trees per hectare every 25 years. Additionally, to combat illegal logging they have developed a program to track logs via bar code markings.

In the past, Gabon exported the majority of its raw timber product to other countries for them to finish. That has changed through government legislation that forbid selling the raw materials directly to other countries (France was a big customer). Now, the government is working to create industrial economic zones that provide tax breaks and other incentives to have businesses build factories and facilities that provide finished forest products right on their own. These include:

- Furniture

- Plywood products

- Veneers from exotic tree species

To assess the interior forestland and track toward sustainable management of such a large area, Gabon officials built a satellite research station to track and create a database of the areas most degraded from industrial activity. This has led directly to a decline in illegal logging and deforestation overall. Some of the areas that were degraded previously were then re-purposed to more industrial agriculture services like palm oil.

This conservation and active sustainable management has led to a boom in the elephant population as well. In the 1990’s, the elephant population in Gabon numbered around 60,000. Now the population has grown to over 95,000. It is said that elephants are a sign of a thriving forest and certainly the elephants in Gabon are thriving.

Gabon and Forest Products

Gabon’s booming veneer business has made it the largest producer of exotic veneers in Africa. Their rich resource of exotic woods has made them a much sought after medium for crafting fine furniture and wood materials. And they are actively developing plywood manufacturing sectors through the grant of special economic zones that are located strategically close to resources and populations in need of employment.

The timber industry in Gabon is responsible for more than 30,000 jobs and this number is projected to increase as workers in the oil and gas sectors transition to forest based jobs. That 30,000 already represents about 7% of their total available workforce.

Gabon and Carbon

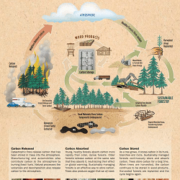

As the second largest reservoir of carbon sequestered through forestland (the Amazon is the largest), the burgeoning worldwide carbon credit market has created new opportunities for Gabon to utilize the natural carbon sequestration of its forest for profit in the CC market. It has sought and received carbon offset certifications from independent auditors.

Though this has not come without controversy as Gabonese officials chose to re-evaluate their credit calculation method and have since quadrupled their available carbon credits into the tens of millions of dollars. The concern is the market being flooded with these credits and thus driving down prices overall and the veracity of the credits themselves. Government officials have pointed to the initiative as a model for using new markets to fund the conservation of their forestland.

While Gabon’s story around forest products as a resource continues to play out over time. The model that they have provided to other African nations has prompted other to develop the same type of resources where available. However, the challenge becomes whether or not these other nations will adhere to principles of sustainable management of forestland and the need for economic opportunity. Time will tell.