Urban Forestry and the Urban Sawmill

Urban trees are everywhere. They shade homes, line streets, and provide those living in the city with a soothing dose of nature. Everyone recognizes their benefits and enjoys what they bring to an urban landscape.

But unlike trees in a natural forest setting, when urban trees are damaged or at the end of their lives, they can’t be left to fall. Instead of providing homes for wildlife and nutrients for the soil, they can create hazards for both people and property.

In the past, the only fate for urban trees was the chipper, the fireplace, or the landfill. Even valuable hardwood removed from yards went unused. When a building was torn down, the lumber often suffered the same fate as those urban trees.

Collectively, the forest products industry is recognizing the value of both reclaimed wood and wood milled from urban trees. The sustainable wood movement is pushing urban sawmills forward all over the country. These small businesses are making a big impact on their communities.

Urban Sawmills

When most people think of a sawmill, they picture an industrial operation. These industrial mills process huge numbers of logs using automated systems for maximum efficiency.

Urban sawmilling is a different kind of sawmill. These mills are not processing raw materials at scale, so they are more compact.

But, they do the same thing as their industrial cousins; they turn logs into usable lumber and other forest products. Urban sawmills simply do so in a more convenient location and on a smaller scale.

An urban sawmill can offer unique benefits that industrial operations do not. These mills are owned and operated by small businesses right in the communities they serve. They create jobs and lumber that can be used by local builders, woodworkers, and other hobbyists.

Urban sawmilling can be done by individuals or small crews. Felled urban trees are often loaded on trailers and brought to the site of a small urban mill. Sometimes a portable mill will be brought to the site of harvested trees.

Removed urban trees are an excellent source of sustainable wood. Urban sawmills are often able to process smaller logs, leading to more usable lumber and less waste.

However, urban sawmilling isn’t a brand new idea. Smaller and more mobile sawmills have existed for a long time. But there was little organization and almost no focus on urban trees. As the wood products industry as a whole focuses on sustainability, initiatives to advance and coordinate urban sawmilling are on the rise.

The goal is to make urban sawmilling accessible, local, and beneficial to the community.

Urban Forestry

Complementary to urban sawmilling is urban forestry. Forest management isn’t only for vast tracts of wooded land. In the United States, over 140 million acres of forested land are in cities and towns.

These green spaces require a different type of management than traditional forests. Urban forestry professionals choose the most beneficial tree species, maintain their cities’ tree canopies, and work with local governments to maximize the health of their natural spaces.

The benefits of natural areas are well established. They provide shade and relief from the heat, clean the air, help filter water, and improve people’s health and wellness.

Over 80% of Americans live in urban communities. Carefully planning, maintaining, and preserving forests in these communities has never been more important. Urban forest managers can benefit greatly by having urban sawmills accessible for service.

Urban forestry depends on cooperation between municipalities, businesses, and individuals. Urban sawmills make it easier and more convenient to dispose of a city tree in a way that benefits the environment and the community.

Urban foresters are also on the front lines of fighting climate change. Milling felled urban trees locally saves energy, keeps carbon sequestered, and creates a local source of sustainable wood.

No one wants to lose a tree from their yard or street. But when it happens, urban forest managers with easy access to a sawmill can reduce or eliminate the waste usually involved in disposing of an urban tree.

The best urban forests are meticulously planned and maintained. Urban sawmills offer an economically beneficial, environmentally responsible way to help keep city forests healthy while giving back to the community.

Locally Salvaged Timber

One of the greatest benefits of urban sawmills is that they are local. Transporting a harvested urban tree to an industrial mill can be inconvenient and expensive.

A tree that is milled locally helps create the type of circular economy that is a key part of practicing sustainability in urban communities.

When a tree is taken down by a city and locally milled, the lumber can be used for community projects or sold. Many urban trees are valuable hardwood that is in high demand for wood furniture, flooring, and other wood products.

Some cities will also have fallen trees that are salvageable. Urban forest managers oversee parks, green spaces, and other wooded areas that are less controlled than a city street or individual yard. They determine if a fallen tree is more valuable as part of the urban ecosystem or as salvaged lumber.

Using urban wood for city projects saves money. Selling it makes money. That money can be used to plant new trees. Most cities and towns have space for many more trees than they plant. Some estimates indicate that cities in the U.S. could support an additional 400 million trees.

Urban sawmills play a huge role in this circular economy. Locally salvaged trees stay local, reducing emissions from transport, supporting local businesses, and keeping the benefit of valuable wood in the community.

Milling locally does more than benefit cities. Urban trees are harvested for a lot of reasons. Disease, old age, and damage are among the most common. Many of them are mature hardwood trees that have been part of their neighborhoods for generations.

As people become more conscious of where their raw materials originate, they prefer local goods of all kinds, wood included. Knowing that the lumber they use is sustainably produced makes it more desirable.

Urban sawmills also help cities, businesses, and individuals make the best use of reclaimed wood. This wood, the product of construction and demolition, can have a useful life in new wood products like furniture and other wood crafts.

Reclaimed wood has a singular beauty. It is weathered, has character, and is an environmentally sustainable way to build. Sometimes salvaged wood is from rare species no longer used for building.

The Future of Urban Sawmills

What started as a few individuals harvesting local trees has spread through the wood products industry. Non-profit organizations are beginning to coordinate and support urban sawmills.

As these networks grow they will provide vital information for cities and other consumers. They can become trusted allies in helping people find reliable sources of sustainable wood.

A well-run network will increase consumer confidence, building the reputation of urban sawmills as knowledgeable and trustworthy. The urban sawmill can become a central cog of the new urban forestry. Accessibility to a mill makes reclaiming urban trees possible and sustainable.

The addition of accessible portable and stationary urban sawmills to an area can transform its urban forestry. Forest managers can make better use of their budgets and their trees while supporting the community.

Harvested city trees, salvaged fallen trees, and reclaimed wood are all valuable additions to the sustainability of the wood products industry. With enough urban sawmills, this wood can provide building materials, jobs, and advance circular economies.

Urban sawmills and other sustainable urban forestry practices help protect city trees and resources. They allow a type of recycling, and upcycling, that brings in revenue and keeps removed trees out of the waste cycle. Their carbon stays sequestered and does not contribute to climate change.

Urban forestry is changing. As more urban trees are milled locally, what began as a trend can become another sustainability success story for the wood products industry.

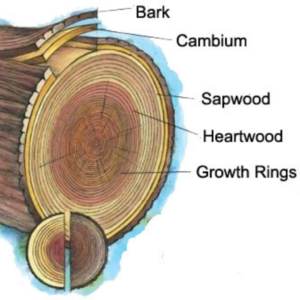

Most of us are familiar with many deciduous tree species, including oak, maple, birch, and apple trees. Deciduous trees are hardwood trees and you see their wood used in items like oak furniture, cherry wood kitchen cabinets, and maple flooring.

Most of us are familiar with many deciduous tree species, including oak, maple, birch, and apple trees. Deciduous trees are hardwood trees and you see their wood used in items like oak furniture, cherry wood kitchen cabinets, and maple flooring.