The Life Cycle Assessment: An Essential Tool For Wood Packaging

In the wooden pallet and container industry, we recognize the growing importance of sustainability in our decision-making processes. To make informed choices about the environmental impact of our packaging solutions, we need accurate, comprehensive data on the materials we use.

The Life Cycle Assessment (LCA) is a valuable tool that allows us to evaluate the environmental performance of wood packaging materials, from raw material extraction to end-of-life disposal or recycling. In this Nature’s Packaging blog post, we’ll explore the key components of the LCA, its applications in the wood packaging industry, and how it can guide us towards more sustainable practices.

Understanding Life Cycle Assessments

A Life Cycle Assessment is a systematic method for evaluating the environmental impact of a product, process, or service throughout its entire life cycle. LCA’s takes into account various stages, including raw material extraction, material processing, manufacturing, distribution, use, and end-of-life management. By analyzing these stages, LCA provides a comprehensive understanding of the environmental footprint associated with a given packaging material, allowing industry experts to identify areas for improvement and make data-driven decisions.

Key Components of an LCA in Wood Packaging

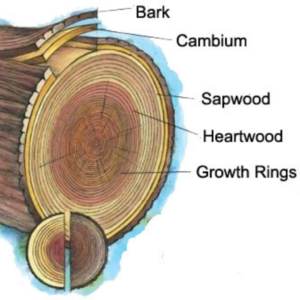

- Raw Material Extraction: In the context of wood packaging, LCA starts with the extraction of raw materials, such as timber from sustainably managed forests. This stage considers factors like land use, biodiversity, and carbon sequestration.

- Material Processing: The next stage involves processing the raw timber into wood packaging materials like pallets or crates. LCA examines the energy consumption, emissions, and waste generated during this phase.

- Manufacturing: The manufacturing stage focuses on the production of wood packaging products, considering energy inputs, emissions, and waste associated with the production process.

- Distribution: LCA evaluates the transportation of wood packaging materials from the manufacturing site to the end-user, taking into account transportation modes, distances, and related environmental impacts.

- Use: This stage assesses the environmental performance of wood packaging materials during their intended use, such as pallet pooling or reusable packaging systems, and the potential for repair and reuse.

- End-of-Life Management: Finally, LCA examines the disposal, recycling, or repurposing of wood packaging materials at the end of their useful life, considering waste reduction and resource recovery opportunities.

Applying the LCA in the Wood Packaging Industry

Life Cycle Assessments are an invaluable tool for industry experts seeking to understand the environmental impact of their wood packaging solutions. Some of the key applications of an LCA in the wood packaging industry include:

- Comparing Materials: LCA’s can be used to compare the environmental performance of different packaging materials, such as wood, plastic, or metal, providing objective data to support material selection decisions.

- Identifying Improvement opportunities: By analyzing the life cycle of wood packaging materials, LCA’s can help industry experts pinpoint areas for improvement, such as reducing energy consumption during manufacturing or improving recycling rates.

- Communicating Sustainability: LCA results can be shared with customers, stakeholders, and regulators to demonstrate a company’s commitment to sustainability and showcase the environmental benefits of wood packaging solutions.

- Guiding Policy and Decision-Making: LCA findings can inform policy-making and decision-making processes at both the corporate and governmental levels, shaping the future of the wood packaging industry in a more sustainable direction.

Leveraging LCA’s for Sustainable Wood Packaging Solutions

As an industry, it is our responsibility to promote sustainability in our operations and messaging. The Life Cycle Assessment is a powerful tool that allows us to assess the environmental performance of wood packaging materials and make informed choices.

By leveraging LCA insights, we can drive continuous improvement, reduce our environmental footprint, and lead the way towards a more sustainable supply chain.

Most of us are familiar with many deciduous tree species, including oak, maple, birch, and apple trees. Deciduous trees are hardwood trees and you see their wood used in items like oak furniture, cherry wood kitchen cabinets, and maple flooring.

Most of us are familiar with many deciduous tree species, including oak, maple, birch, and apple trees. Deciduous trees are hardwood trees and you see their wood used in items like oak furniture, cherry wood kitchen cabinets, and maple flooring.

Woodview Media

Woodview Media