Today I Learned-Wood Stringer Pallets-Part 1

For those in the wood pallet industry, pallet types, pallet parts, and vocabulary are second nature. The terms and topics are a part of doing business everyday.

For those outside of the pallet industry that may be tasked with buying pallets, these terms and topics can be difficult to understand or there may be some gaps in understanding.

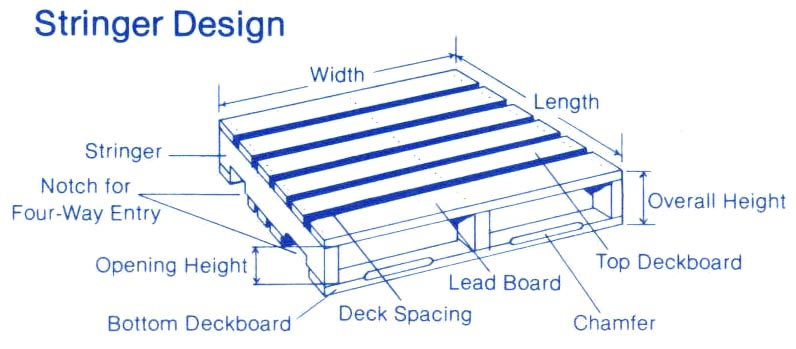

So today, we at Nature’s Packaging want to help you (the pallet buyer) with a short and simple guide about the most common wood stringer pallet in the supply chain and some of the terminology around it, the 48×40 wooden stringer pallet (shown above as the featured image).

The 48×40 Wooden Stringer Pallet

While there a certainly a whole range of wood pallets sizes in the the supply chain, the standard 48″x40″ wood pallet is by far the most common and utilized for transporting goods. The 48″x40″ is also sometimes called a “GMA” pallet. GMA stands for, “Grocery Manufacturers Association” and the GMA pallet is a guideline developed by that association to help streamline transportation of products within the food industry.

As seen in the image above, the standard 48″x40″ pallet is usually composed of a few different components:

- stringers

- deck-boards

- fasteners (nails)

Stringers – also known as “runners”, are a continuous length-wise beam component that acts as support for deckboards and allows the deckboards to be spaced apart according to the needs of the pallet user. On a typical 48×40 pallet you will find 3 stringers spaced evenly apart with a center stringer and two at the edges.

Notice the notches in the stringers in the image above. A standard 48×40 stringer pallet is also known as partial 4-way pallet. This means that a forklift or pallet jack can enter from the front or back of the pallet to move the load, but only a forklift can lift a 48×40 pallet by coming in from the side using the notches. Most pallet jacks will not fit in the space.

Deck-boards – wooden components typically nailed perpendicular across the top and bottom of the pallet to the stringers. Deck-boards are spaced according to the needs of the pallet user and their unit load. The top and bottom deck-boards that sit on the front and back edge are commonly known as the lead boards and the others are the interior deck-boards. Typical configurations for the number of top and bottom deckboards on a 48″x40″ pallet are 7 top deck-boards and 5 bottom deck-boards. Many times you will find the lead boards are wider than the interior deck-boards, this aids in stability and can help lower the repair rate due to forklifts running into the edge frequently.

Sometimes the bottom deck-boards will be “chamfered”, this a beveled cut along part or the full width of the deck-board to help with the passage of the pallet jack forks into the pallet.

Fasteners – or “nails” are almost always threaded, rather than a common nail used in carpentry, as the threading will help with the pallet durability and strength. Usually 2-3 nails are used per deckboard to secure it to the stringer. Here is a sample below for better understanding.

Pallet Size

When discussing a wood stringer pallet with your supplier, the pallet length and width are based on the stringer length and deck-board width respectively. So a 48″x40″ stringer pallet has 48″ length stringers at full length and 40″ deck-boards across. Pallet size for a stringer pallet ALWAYS starts with the stringer length. Remember that.

Pallet Build Types

A 48×40 wood pallet can be built several different ways. What this refers to is the components used for building the pallet. The following are different build types:

- New

- Combo

- Remand

- Recycled

New – A wood pallet built with all new components

Combo – A wood pallet built with a combination of new and recycled components. Typically the stringers would be new and the deck-boards would be recycled. Often a more cost effective alternative to completely new pallets.

Remand – A wood pallet “re-manufactured” from recycled components entirely (except for the nails used). Often, these will be a smaller size than a 48×40 pallet as the components are recycled from the larger pallet size. 36×36 pallets are a common size for remand pallet.

Recycled – A wood pallet that has components repaired so that it can be re-used. Typically, this will be some number of damaged deck-board components that are removed and a “new” recycled deck-board is nailed back into place. There can also be a companion stringer, otherwise known as a “plug” or “crutch” that is nailed alongside the interior of a stringer to act as support when the original stringer is cracked or partially broken.

Wood pallets have a 95% recycle rate which makes the industry one of the most environmentally friendly in the supply chain services. We at Nature’s Packaging hope that this quick guide will help you when making decisions to purchase pallets. Always work with your pallet services provider to help you find the solution to your pallet needs.

*The National Wooden Pallet and Container Association has an excellent resource library that contains documents like the Uniform Standard for Wooden Pallets that provide an in-depth review of the subject matter. Please use the links to visit the library and learn more.