Avoid These 6 Mistakes When Buying Wood Pallets

When it comes to buying wood pallets, there are several factors to consider. Modern Materials Handling Magazine’s 2018 annual survey found that purchase price was the most important factor in the selection process for 57% of respondents, although this was down from 59% and 60% in the two preceding years. Other criteria registering high scores included strength, durability, reusability, availability, meeting customer requirements, and cost-per-use. Here are some missteps to avoid.

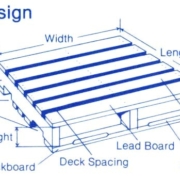

Relying on outdated wood pallet specifications

Supply chains evolve over time. Companies acquire other companies that have different equipment and processes. Even at existing plants, investments in material handling equipment, evolving product offerings, and a changing customer base may all present new challenges in transporting the unit load on a legacy pallet.

A periodic review of the pallet specification with your pallet supplier can achieve continued unit load optimization, even as the supply chain transforms.

Approved pallet supplier cannot perform a site visit

As a busy pallet buyer, it can seem inconvenient to allow approved bidders on site to review pallet conditions and processes, especially considering COVID-19 precautions. It is an essential part of the process that will pay dividends.

A site visit allows the bidder to accurately capture important information about the pallet application, and in a timely manner. This approach can help expedite the bidding process. A site visit can also help pallet suppliers identify cost savings opportunities or other insights that can provide value to pallet users.

Inflexible on hardwood vs softwood pallet types

In the United States, the West and the South are more commonly associated with softwood, while the East is typically oriented to hardwood production. Pallet specifications can propose either hardwood or softwood in their build.

However, if a new plant begins operations in a different part of the country, or if comparative prices of hardwood and softwood change due to market conditions, it makes sense to revisit the pallet specification with regards to available lumber supply.

When market volatility increases the spread between hardwood and softwood prices, it can make sense to explore pallet redesign options with a pallet supplier.

ISPM-15 Heat treatment and mold on wood pallets

There is a common conception that the heat-treatment required for ISPM 15 compliance will help to prevent the occurrence of mold on pallets.

While heat treatment will initially kill surface mold on pallets, mold can easily re-colonize wood pallets that have a moisture content of more than 19%. A better approach to mold prevention is assuring that pallets arrive in a dry condition from the pallet supplier and that they are kept dry when received and put into storage prior to use.

Overlooking transportation opportunities

Products such as pallets have a relatively low value in comparison to their weight and volume. Such products are referred to as having a low value density.

Given the low value density of pallets, transportation can quickly become a significant portion of pallet cost. At the same time, the number of trucks running empty is significant, estimated at 20% or higher. By working with pallet suppliers to examine carrier and route information, possible synergies can be identified to help reduce costs and transportation miles.

Underestimating the value of customer service

When buying pallets, there is more to consider than price. Do not underweight the importance of customer service. Your company will have expectations about reliable quality and availability, delivery schedule, type of delivery vehicle, whether pallets are banded, and more.

Shortcomings in customer service can result in costly downtime, double handling, and customer dissatisfaction. The result can be increased production and distribution costs, and potentially lost revenue. The direct savings in pallet purchases can become overwhelmed by increases in indirect cost.

The list of false steps mentioned above provides a useful starting point in addressing the blind spots that pallet buyers can encounter. The common thread in these cautions is the importance of keeping an open line of communication with your pallet supplier. Communication and trust are critical to optimizing the purchase of new pallets for your supply chain.