For some people, the words “sustainable” and “logging” simply do not go together. Historical logging practices were sometimes hard on forests and disrupted native ecosystems. Today, sustainable forestry practices that include logging and harvesting trees comfortably co-exists with the conservation of thriving forests.

Sustainable Logging: The Beginning

Historical logging practices began with the axe, manual saw, and manpower. They were transformed by the introduction of powered machines. At first, as volumes of timber increased exponentially with these new capabilities, the harvesting practices remained tied to traditional practices for some time. The practice disrupted wildlife, native plant species, and the enjoyment of wild areas.

While clearcutting is still practiced today, it is more controlled and meant to optimize renewal growth.

As environmental and climate awareness began to rise, bitter confrontations with the logging industry became far too common.

In 1972, the U.S. embarked on a new path. With the passage of the Clean Water Act, environmental policies were written into law across the nation. Local, state, and federal regulations emphasized healthy forests and responsible management.

But logging couldn’t simply stop. The industry supplied, and continues to supply, much-needed timber and other forest products to consumers around the world. The harvesting of forest products provided the economic foundation for communities across the country.

Reconciling those competing needs resulted in the birth of sustainable logging practices. Old-style clear-cutting both destroyed forests and ended the economic viability of the land. Sustainable practices allow both to flourish.

Sustainable logging practices benefit everyone, from the employees of logging companies to the campers enjoying a weekend in the woods.

Sustainable forestry even has the potential to help mitigate climate change.

Sustainable Logging Overview

The main principle of sustainable logging is to balance the economic importance of forest products with the ecological importance of healthy forests. This requires a comprehensive strategy for every potential logging site.

One way to approach sustainability is to design harvesting to mirror the effects of nature. Forests are altered by wind, fire, flood, and other natural events. Trees die and are replaced in forests with no human intervention.

Sustainable forestry also depends on choosing harvesting sites wisely. Old growth forests that are not normally harvested commercially should be left alone, preserving ecosystems and habitats that have flourished in place.

For land with a history of logging, sustainable logging begins with foresters learning as much as possible about the natural patterns and existing conditions of each tract of trees.

Sustainable Logging Practices

No two tracts of land will be logged in exactly the same manner. Sustainable logging brings together a team of experts who compile a comprehensive analysis of the area. Biologists, geologists, ecologists, and more lend their expertise to each project.

Each project has its own profile. But similar sustainable logging practices are adapted for sites across the country and, increasingly, around the world.

Patchwork Logging

While a company used to clear-cut an entire forest, sustainable logging is far more targeted and precise.

Harvesting trees from a small area allows the surrounding forest to adapt to the clearing like it would to a natural event. Keeping harvested areas far enough apart maintains habitat and biodiversity.

Tree type and growth, soil conditions, and other factors determine how many trees can be harvested from an individual area. In places where fire or damaging storms are common, the overall environment may be able to regenerate a larger area.

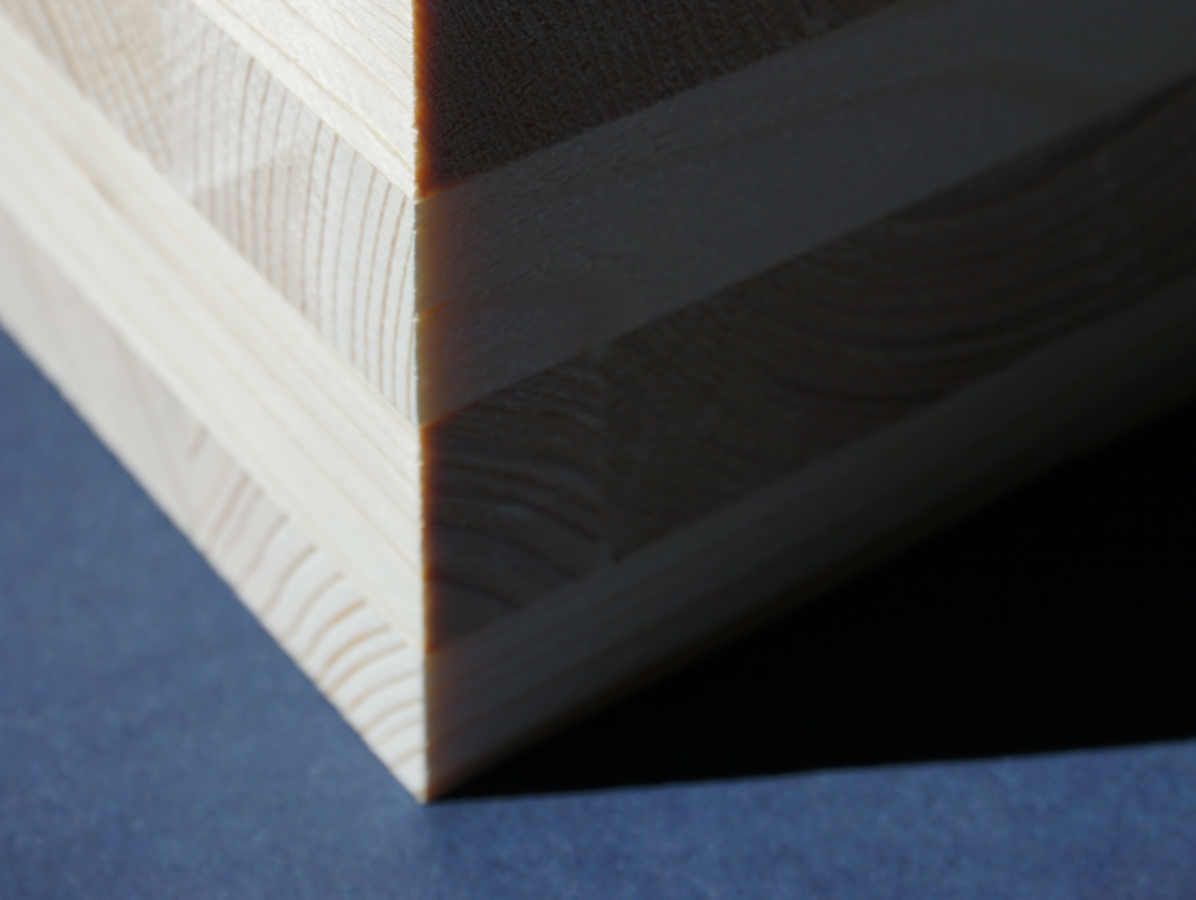

Patchwork logging leaves trees within a harvested area to better mimic natural conditions. It also allows for the preservation of tree species that are endangered or play an oversized role in ecosystem balance.

Sustainable logging is done in cycles. Some models propose that a cycle be no shorter than 80 years. This allows the forest to recover and continuously produce harvestable trees.

Areas that have been harvested are planted with saplings. The emergence of wild grasses attracts wildlife to the clearing, and the ecosystem evolves and grows.

Selective Harvesting

Selective harvesting removes individual trees, thinning the forest to allow existing smaller trees more space and light to grow. This type of sustainable logging is especially beneficial in tropical areas that don’t have natural events that mimic areas of clear-cutting.

Selective harvesting preserves undergrowth. This helps prevent soil erosion and maintain the health of the larger ecosystem.

Both patchwork and selective sustainable logging use fewer and smaller roads and less equipment, reducing damage to the surrounding forest. Careful attention is paid to the protection of unharvested trees.

Other Benefits of Sustainable Logging

Sustainable logging offers additional environmental benefits. Harvested trees and areas are kept well away from waterways to minimize erosion and runoff. Sufficient space is left between harvested areas to provide an uninterrupted habitat for wildlife.

Sustainable logging also provides a safer working environment. Fewer people and less equipment in each area help reduce the chance of accidents.

Sustainable Logging: Forest Management and Climate Change

Sustainable logging can play a major role in forest management. An unlogged forest is not necessarily a healthy forest. The work that goes into profiling a forest or tract of trees before harvesting provides valuable information.

That information includes soil, geography, and tree health analysis. Invasive species are documented, as are biodiversity, wildlife habitat and density, erosion, and any disease or damage present in the area.

Logging is sometimes the first step in returning a forest to good health. Removing diseased, damaged, or low-quality trees helps the higher quality trees grow. This is called an improvement harvest.

The branches and other wood left behind by this careful removal provides wildlife habitat while it decays and enriches the soil. Removing invasive trees, vines, and other plants provides better conditions for the remaining trees.

Sustainable logging practices are used and adapted by forest managers to improve the overall health of their woodlands, even if no trees are harvested for lumber.

Sustainable forestry is also becoming the focus of climate action. Sustainable logging can result in more trees as well as healthier trees able to capture more carbon.

Tropical forests are an area of particular interest for climate action. 1.5 million square miles of tropical forest are currently being selectively logged. Widespread adoption of selective harvesting practices would allow these forests to maintain much of their carbon stores and biodiversity while continuing to anchor economies.

Sustainable logging practices combine common sense, careful study, and new technologies to improve the health of forests around the world. At the same time, they provide economic stability for many communities and meet the continuing demand for lumber and other forest-based products.