Windows to Wearables: Innovation in Wood Products

While wood products have been used by humanity for millennia, researchers are recently finding new and exciting ways that the material can be used to promote sustainability. The forest products sector welcomes these exciting new opportunities for wood products, particularly for its woody residuals such as sawdust, bark, and chips. Woody residuals are generated from tree harvest tops and branches, woodlot thinnings, low-grade logs, sawmill activities, and the chipping of recycled wood, including end-of-life pallet material.

Woody residuals are used for various purposes, including mulch, soil amendments, playground surface material, boiler fuel, pellets, as well as fiber for pulp and structural panels such as OSB. Demand in many market segments is healthy. In some cases, in fact, it is booming! COVID-19 helped provide a “turbo boost” for wood residual products associated with consumers such aslandscaping mulch and home heating pellets as people have been spending more time at home and investing in home improvement projects.

Other market segments can be more fickle. One of the key challenges faced by wood product producers is that wood fiber is not economically feasible to ship great distances due to its low value. A common rule of thumb is that wood chips and sawdust are not profitable to ship more than 100 miles.

For this reason, wood fiber markets tend to be highly localized, depending upon the local demand for fiber products. If wood producers in an area are dependent upon a large local consumer of residuals such as a pulp and paper plant, and the local source is lost, it can leave businesses scrambling to find an outlet.

One particular challenge has been the closure of pulp and paper plants. In the case of the newsprint market, we are witnessing a decline in demand as people increasingly embrace digital media. In 2019, the global demand fornewsprint plunged 13% from the previous year. In 2020, thedemand for newsprint in Europe dropped by a whopping 20.5%.

Given the significance of that decline, it will be important for the forest sector to identify new markets for its woody residuals. One area of active research and investment is in bioproducts, a fast-growing category of products that include biochemicals, biomaterials, and bioenergy.

Wood Insulation for Buildings

Wood fiber home insulation is a $700 million market in Europe, supported by 15 production plants and offering insulation products with a much lower carbon footprint than alternatives. While the product line has a proven track record in Europe dating back over 15 years, it has not been produced in the U.S. That situation is about to change, with a new wood fiber insulation plant scheduled to begin production in 2022.

Equipment for the new Maine production plant has arrived from Germany. The facility, which will support up to 130 employees when at full production, is utilizing a shuttered pulp and paper plant. It will use woody residuals as feedstock, providing a valuable market for that material.

The plant will produce three products, including insulated board, batt, and loose-fill wood fiber. According to the manufacturer, the carbon footprint of the wood insulated board is four times better than that of foam plastic boards and seven times better than mineral wool board, its main competitors. For batt, the carbon footprint is five times better than fiberglass and seven times better than mineral wool. Other beneficial features of note are that the products don’t trap moisture, and they can be recycled without specialized equipment. They are also non-toxic and biodegradable.

Wood Fiber Clothing

A company based in Finland has been developing more sustainable alternatives to fiber materials such as cotton and rayon that rely on the use of chemicals in processing, which in turn can lead to water pollution and employee health issues.

The company’s production process turns wood material, including biomass, into a material called micro fibrillated cellulose, which in turn can be manufactured into eco-friendly clothing. The only production byproduct is evaporated water, and its process consumes a much smaller amount than would be required for cotton production. The company recently entered a 50-50 joint venture to build a $61 million plant to produce clothing fabric from wood pulp, scheduled to open in 2022.

Transparent Wood

Glass is commonly used for windows, but experts note that it comes at a significant economic and environmental cost. Regulating building temperatures accounts for 14% of primary energy consumption in the U.S., and one-quarter of this energy is lost through inefficient glass windows in cold weather.

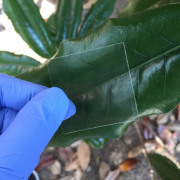

Transparent wood windows, on the other hand, boast a thermal conductivity more than five times lower than glass, and toughness three times greater than glass. Earlier attempts to make transparent wood involved removing lignin through the use of toxic chemicals and high temperature, but it was an expensive product and the resulting product was brittle.

Researchers have developed a new cheap and effective method to produce transparent wood, however. A thin veneer of rotary cut wood can be treated with a solution of hydrogen peroxide, and after an hour in the sun or under a UV lamp, the peroxide bleaches out the color but leaving the lignin intact and the wood turned transparent. While this technology has yet to commercialized, the researchers feel it holds great potential as a new building material.

Research continues in the development of cellulose-based innovations that provide a lower carbon footprint than existing products, without compromising performance. Some of these products offer the potential to better utilize woody residuals while underscoring the importance of our forest resource.