Innovation in Wood – Cross Laminated Timber

The W.A. Franke College of Forestry and Conservation at the University of Montana is just one of an increasing number of institutions looking to cross-laminated timber (CLT) for new construction. UM recently requested money from the state legislature to help fund the building of its new $45 million CLT building, to be built from wood grown, harvested, and manufactured in that state.

“It just makes perfect sense for a forestry building and tells the story, and it is a much more sustainable and reasonable way to go,” Alan Townsend, the Franke College dean, told The Missoulian. “And it can look really cool. It’d be a pretty iconic building on campus.”

Based on its earlier adoption in Europe as a building material, interest in CLT structures continues to grow in North America and around the world. Buildings manufactured with CLT panels are faster to construct, more energy-efficient and made from renewable material. Let’s take a closer look.

What is Cross Laminated Timber (CLT)?

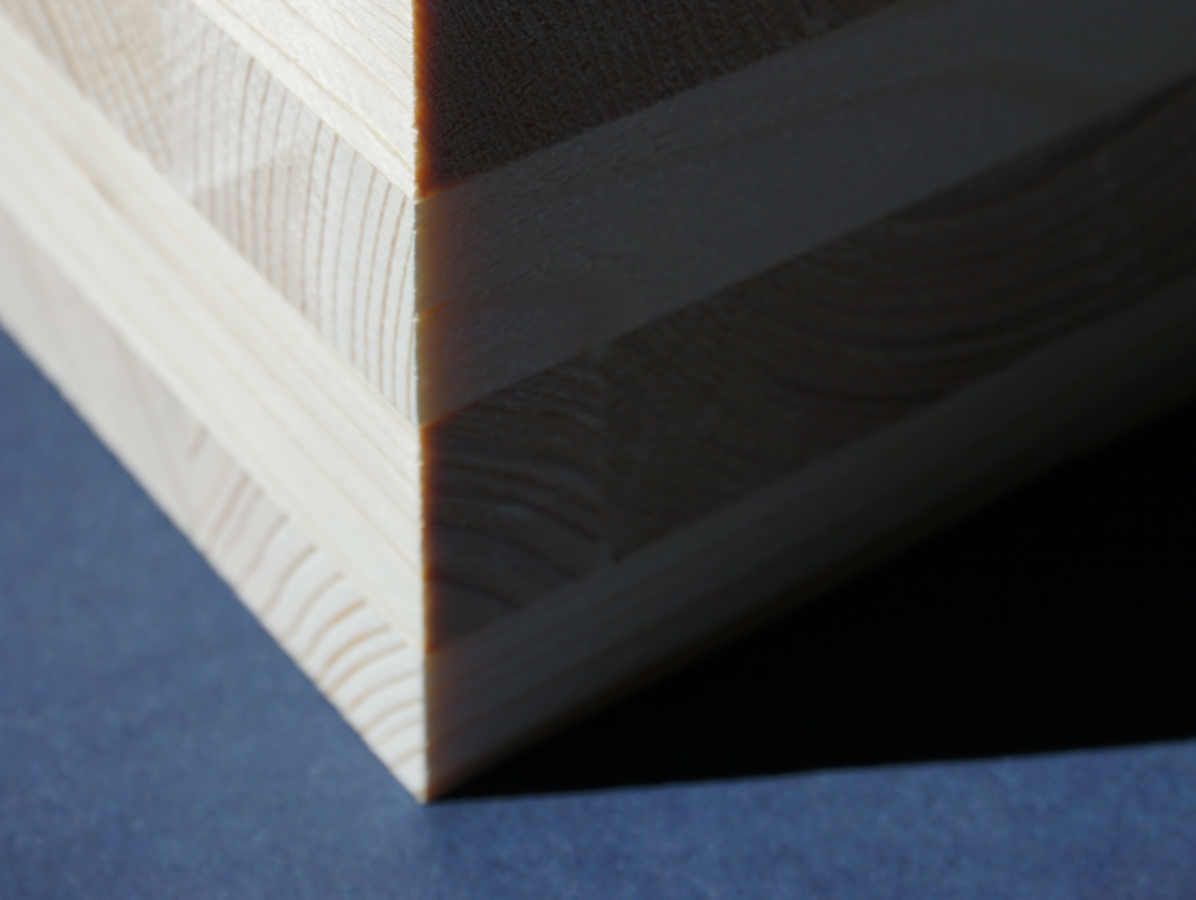

Cross-laminated timber (CLT), a sub-category of engineered wood, is created by gluing together several layers of kiln-dried lumber. Laid flat, they are glued together on their wide faces, with grain in alternating directions at 90 degrees.

Panels most frequently consist of three, five, seven or nine alternating layers. Layer thickness typically ranges from ⅝” to 2” and board width from 2.4” to 9.5”. It is similar to plywood, however with significantly thicker laminations or layers. The layered stacks are glued and then pressed vertically as well as horizontally to create panels, which can then be accurately sized and finished for installation.

Typical panel widths are 2, 4, 8 or 10 feet, while panel length may extend to 60 feet. CLT is different than glued laminated timber (glulam) in which all laminations are oriented in the same direction.

What is the History of CLT?

Cross-laminated timber was first introduced in the early 1990s in Germany and Austria. Since that time, it has continued to gain popularity for residential and non-residential building construction in Europe.

After slow initial growth, its popularity began to increase in the early 2000’s thanks to the green building movement, as well as through newfound efficiencies, product approvals, and improved marketing and distribution.

CLT usage in buildings has increased significantly in the last decade. Hundreds of impressive buildings and other structures built around the world using CLT bring to life the substantial benefits made possible by CLT. The European projects demonstrate that CLT construction can be competitive, particularly in mid-rise and high-rise buildings.

What are the Advantages of CLT?

According to www.woodworks.org, the major benefits of CLT are listed as follows:

Design flexibility: CLT panel thickness can be easily increased to allow for longer spans, and custom cut as required with CNC equipment to exacting tolerances.

Thermal performance: CLT’s thermal performance is related to panel thickness. Thicker panels require less insulation, and because panels are solid, there is little potential for airflow through the panel system. As a result, interior temperatures can be maintained with as little as one-third the amount of energy otherwise required for cooling or heating.

Cost-effectiveness: Even without considering the added benefits of faster construction time (up to 25% less time and up to 50% less labor) and lower foundation costs, CLT compares favorably to certain concrete, masonry, and steel building alternatives. According to a 2010 study by FPInnovations, CLT was 15% lower for mid-rise residential, 15 to 50% cheaper for mid-rise non-residential and 25% cheaper for low-rise commercial structures.

Less waste: Because CLT panels are custom manufactured for particular building projects, they generate little or no job site waste generated. Additionally, fabrication scraps, if created, can be used for other architectural elements such as stairs, or as biofuel.

Environmental advantages: Aside from superior thermal performance that saves building operators money on their heating bill, CLT is also valued because its production has a lower environmental footprint than the manufacturing of other construction alternatives, including the production of less air and water pollution and the generation of less CO2. The environmental case for CLT is enhanced as it acts to sequester carbon.

Fire protection: The thick cross-section of CLT panels provides superior fire resistance because panels char slowly. Once charred, the panels are protected from further degradation.

Seismic performance: Thanks to its dimensional stability and rigidity, CLT performs well under seismic stresses. Extensive testing has determined that CLT panels hold up exceptionally well with no deformation, particularly in multi-story applications.

What is the Outlook for CLT?

While mass timber is considered a more sustainable building material than steel or concrete, its uptake until recently has been limited due to negative perceptions regarding its strength and cost as well as building code restrictions that have limited its use in mass-market building types.

However, as one recent report notes, as the price of mass timber products continues to fall and local jurisdictions improve their code approval processes, the wood material is anticipated to become a more viable everyday choice for building commercial office buildings.

According to The Economist, mass timber is expected to account for US$1.4bn of the US$14trn global construction industry by 2025 and 0.5% of new urban buildings by 2050. With concerted investment in global manufacturing capacity and building projects for mass timber, however, The Economist believes that the share of the construction market could rise exponentially by 2050, capturing trillions in value.

Resources: