Dynamic Duo: The wood pallet and warehouse forklift

The Dynamic Warehouse Duo

It seems like the pallet and the forklift have always been part of shipping and logistics in the modern world. For 70 years, this dynamic duo has delivered the goods for a growing global economy. While they have served us faithfully, changes in technology are coming fast.

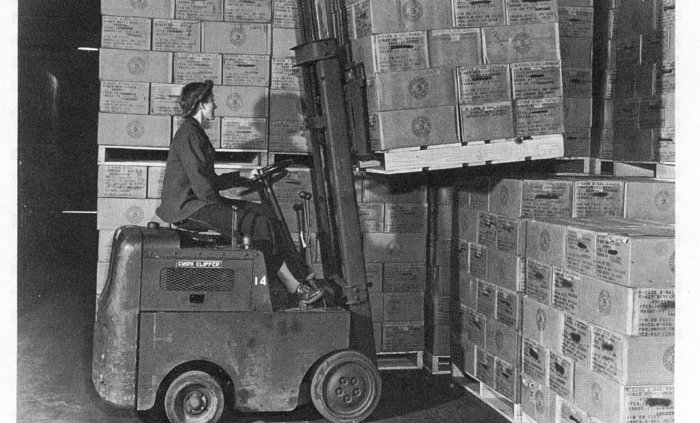

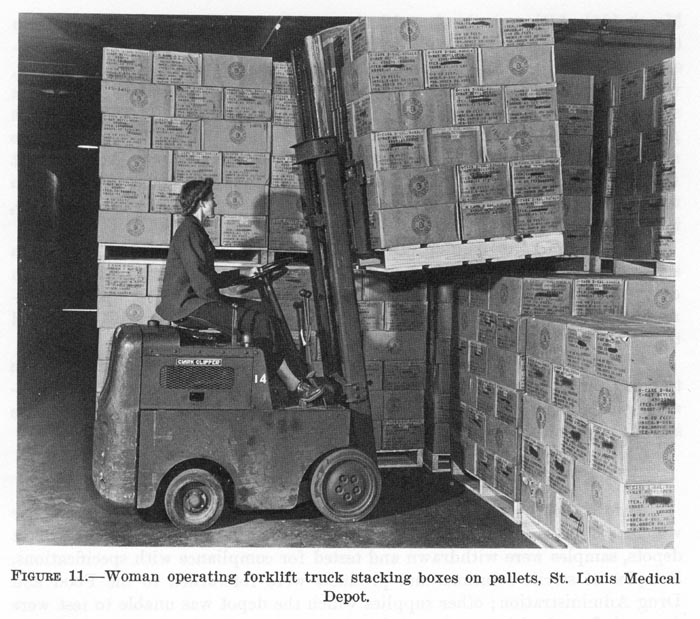

The forklift is no longer the lift truck that Rosie the Riveter drove during World War 2. The venerable material handling mainstay is having a moment among warehouse technologies. New power sources, such as lithium-ion and sealed lead-acid batteries, help promote uptime and reduce maintenance. Meanwhile, the availability of telematics technology for forklifts allows businesses to collect and analyze usage data with an eye toward continuous improvement.

Automated Forklift Technologies

Consider that driver wages to operate a forklift two or three shifts daily can vastly exceed the cost of the forklift and maintenance. As one vendor pointed out, think about the financial impact of running that forklift on three shifts at $50,000 per shift/year. That is $150,000 per year in wages for one forklift! Self-driving forklifts have the potential to help companies reduce costs and ease staffing pressure while increasing productivity and safety.

Several major forklift providers now offer automated options, and the segment is pegged to grow. The automated forklift market is projected to reach $12 billion in sales by 2027, carving out close to a 15% share of the $81.4 billion global forklift market.

In 2019, Amazon raised eyebrows when it made a deal with Balyo, a France-based autonomous technology supplier. The agreement allowed it to acquire 29% of Balyo if it purchases $340 million worth of forklifts featuring the Balyo technology over a seven-year term. Some automation technologies are more sensitive to pallet quality than others, so we would do well to consider the impact of automated forklifts on pallet requirements for fulfillment centers and plant operations. It is something that pallet providers and operations managers alike will wish to know. Will the pallet have to change in keeping pace with the forklift, now seemingly amid a full-blown makeover?

Challenges in the supply chain

The first thing to consider is that variability is often a challenge for automated systems. For applications such as automated storage and retrieval systems (AS/RS) or shuttles, wood pallets that vary in height or specification, even slightly, can cause jams and downtime.

The requirements for mobile robotic lift trucks are not as demanding, yet still require a degree of uniformity. While a human operator can spot a damaged or non-conforming pallet and resolve the issue, such is not the case with automated forklifts.

As mentioned, pallet variability due to pallet specification or because of damage can cause performance issues with automated forklifts as well. “The biggest challenge with mobile robotic lift trucks is variability,” one forklift executive told Pallet Enterprise last year. He noted that variability-related hurdles could extend to floor condition and other aspects of the warehouse environment, including unwelcome surprises involving the pallet/load engagement. “As such, pallets have a substantial impact on the success of any mobile robotic lift truck application,” he said.

Another vendor recommended using highly durable alternative material pallets but was quick to add that automated lift trucks can work with wood pallets as well, but that “worn, broken or bowing” characteristics in pallets can be problematic.

“As robotics continue to penetrate deeper in the conventional lift truck market, the consistency of GMA pallets and the consistency of any GMA #2 pallets will be increasingly rigorous,” the forklift executive continued. “This drives customers and suppliers towards a more stringent definition of what an acceptable pallet is in a system with robotic equipment.”

With continued investment in automation in general, consistent pallet quality will be increasingly important. The good news is that many companies already have pallet quality assurance processes in place, and those operations will be in good shape to adopt automated technology. The best wood pallet for the job will continue to be one that is managed to ensure reliable performance. The dynamic duo of wood pallet and forklift seems poised to continue their partnership, even as supply chain technologies evolve.