Forest Products: Science and Sustainability

America’s treasured forests are brimming with resources that help society thrive. As well as offering locals and vacationers a place to hike and unwind, wooded areas provide access to goods, including construction materials, paper, packaging, and lumber for homes and commercial buildings. In some cases, forest products can even be used in medical and dietary supplements, and as fuel for vehicles. Put simply, contemporary lifestyles are utterly dependent on forests and their many resources.

Of course, efficient use of forest resources requires us to pay careful attention to issues surrounding sustainability and conservation. The Forest Products Laboratory (FPL) – based in Madison, Wisconsin – is one of several research facilities promoting responsible practices in the forestry industry.

In conjunction with other government agencies and public and private companies, the FPL explores how we can continue producing essential forest products while protecting against wildfires, invasive species, and other issues related to climate change.

In this article, we’ll explore what kinds of products the FPL is currently investigating and how they’re pioneering a science-first approach to forestry. Key areas of research include:

Advanced Composites

Wood composites are materials manufactured using many different forest materials such as tree fibers, wood flakes, wood waste, and natural bio-fibers like corn straw and poultry feathers. Wood composites can help reduce the production of waste materials and enhance the economic efficiency of forest reconstruction projects.

The FPL continues to find new ways of producing composite materials, many of which are utilized in home furnishings and major construction projects. More specifically, advanced composites are often used in interior paneling and the support structures used to erect new buildings. As well as helping to protect forests and reduce waste, composite wood is light, durable, inexpensive, and easy to work with. In future, the FPL hopes to design composites offering even better durability and serviceability.

Advanced Structures

Advanced structures are wood products commonly used in residential homes, commercial buildings, and transport infrastructure. Typically, these products offer strength, cutting-edge design, moisture control, and a range of coatings and finishes.

Lumber has been used as a vital construction material for millennia thanks to its durability and affordability. Excitingly, advanced wood structures can even help tackle climate change thanks to their recyclable nature and ability to store carbon. As such, wood carries a lower environmental footprint than steel and concrete. Given the clear benefits of lumber, the FPL continues to research ways of boosting its efficiency and sustainability.

Forest Biorefinery

Wooded areas represent some of the world’s richest sources of biological chemicals and fuels. What’s more, they don’t require pesticides or fertilizer like other sources of biological by-products such as corn and rice. As such, the FPL is committed to researching how to enhance bio-refinery technologies to produce valuable chemicals and fuels for transportation.

Currently, biological products are produced by hydrolyzing wood into sugars. These sugars are then fermented to create ethanol or other fermented substances. The FPL is researching new ways to modify yeast DNA to boost the level of ethanol produced during this process.

In many ways, this research couldn’t come at a better time. As wooded land fills up with overcrowded trees and wooded waste, we’re presented with new opportunities to clean up the forest and satisfy an ever-growing need for alternative fuels. However, harvesting biomass for the production of chemicals and fuels is costly and time-consuming. As such, we must find more cost-effective ways to remove biomass from forests.

Nanotechnology

Nanotechnology represents a cutting-edge field within the multi-disciplinary spheres of science and technology. Broadly speaking, it refers to the analysis and engineering of matter at the molecular and atomic scales. To put the practice into perspective, a nano-meter is equivalent to one billionth of a meter.

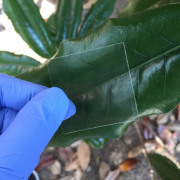

So, how does nanotechnology relate to forestry and wood products? Well, scientists are currently researching and developing wood-related materials and systems that comprise different chemical, physical, and biological properties than materials found on a bigger scale. Researchers at FPL, for example, are conducting studies at the nano-scale to explore under-explored components of wood.

Our increasing ability to explore and manipulate materials at such as small scale is exciting for researchers in the engineering and technology sectors. Nano-materials could be added to everything from cement to cloth products to increase their durability and sustainability. In some cases, they could even be used to produce heat-resistant materials. More specifically, nano-cellulose holds promising potential as an inexpensive substitute for non-renewable materials across virtually all manufacturing sectors.

Woody Biomass

An alarming trend in recent years, the US has experienced a growing number of intense wildfires in recent years. Part of the reason for this increase relates to the fact that US forests contain significant levels of underutilized and small-diameter wooded materials. Such overcrowded forests raise the risk of fires developing. What’s more, they’re prone to infestations and disease.

What’s the solution to this dangerous problem? Traditionally, forests have been thinned out to reduce the risk of fire and keep forests healthy. However, this process is relatively costly and could exceed the value of the forest products collected during removal.

As such, the FPL has been researching the best ways to use the by-products of thinning, helping local communities threatened by wildfires make the most of woody biomass. Currently, the FPL is looking at the potential use of small-diameter wood in large structures such as sheds, bridges, trail paths, picnic shelters, and other buildings that may benefit from a rustic look.

Forest Products = Positive Change

There are plenty of innovative ways for communities and businesses to utilize wood and forest by-products. In future, the industry is likely to shift toward even more sustainable processes, with the goal of helping companies and communities become more ecologically aware and have a more positive effect on climate change.

Woodview Media

Woodview Media