Introducing the Chemical Pallet Pool

There are several pallet pools that provide quality assured pallets for their respective supply chains. Pallet pools offer standardization and the opportunity for pallet reuse and environmentally friendly pallet solutions.

The CP or chemical pallet pool is one pallet pool you might not have heard about. It is well established in the chemical sector, particularly in Europe, but not well known outside of it. Increasingly, however, it is becoming global in scope, and more pallet customers are asking about CP pallets.

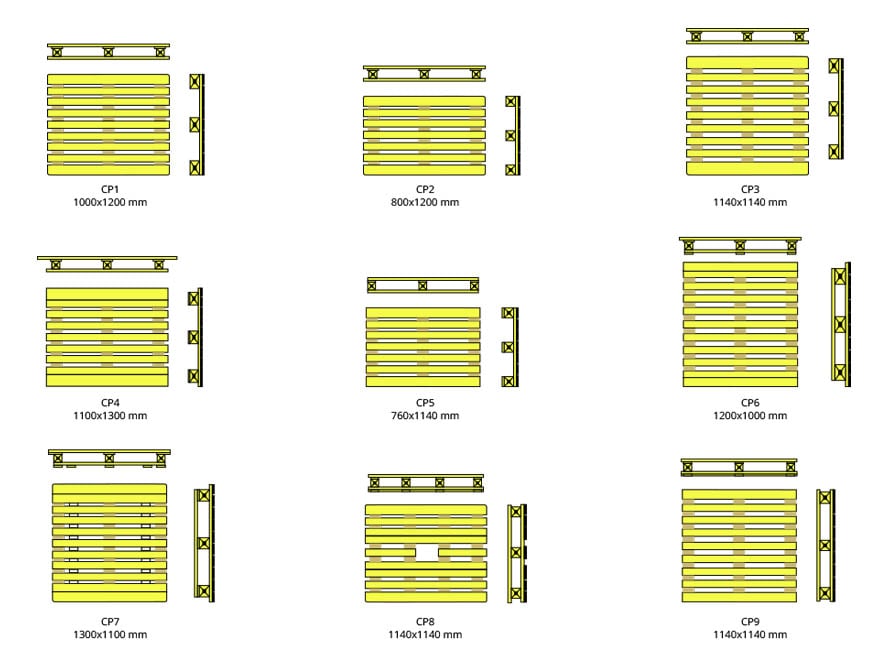

Several million CP pallets are produced annually, and they are readily identifiable by the CP pallet stencil on them. There are nine different CP pallet specifications, ranging from CP1 to CP9.

CP pallet markings include the CP pallet number as well as the manufacturer code, pallet reconditioner, if applicable, and the month/year of production. The ISPM 15 stamp is also required for international shipment. The latest specifications for CP pallets can be viewed here.

The CP pallet pool organizers created strict quality guidelines for pallets in the extremely sensitive chemical supply chain. While the pool is European in origin, the increasingly worldwide nature of the chemical supply chain is making the CP pallet more relevant than ever for North American shippers fielding requests for shipments to be made on CP pallets.

For pallet buyers looking to source CP pallets, it is important to communicate clearly with customers and understand their requirements. They may or may not have issues with “knock-off” or used CP pallet quality that should be vetted with them prior to shipping to avoid costly rejections or delays.

Such concerns are explored later in this article. Beyond chemical industry applications, however, CP pallets are often in demand for other applications where their block design makes them popular.

The CP pallet pool was established in 1991 by the VCI (Verband der Chemischer Industry) in Germany. Pool oversight subsequently passed to the APME (Association of Plastics Manufacturers in Europe), now Plastics Europe. Over the last few years, the European Pallet Association (EPAL) has also expanded its pallet range to include quality-assured EPAL CP pallets.

In the past, EPAL noted in a 2017 announcement, “price competition and the lack of independent quality assurance have often meant that chemical pallets have not met the requirements for the safe transport of chemical products.”

In many pools, there is a trade-off between standard pallets and unit load optimization. The CP pallet pool addresses this issue by incorporating several sizes. The most popular CP pallet sizes in North America are CP1, CP3, CP7 and CP9.

Typical applications for various CP pallets are as follows:

● CP1 pallet (1200 x 1000 mm) – boxes and sacks

● CP2 pallet (1200 x 800 mm) – carton boxes and sacks

● CP3 pallet (1140 x 1140 mm) – drums and bulk bags

● CP4 pallet (1100 x 1300 mm) – sacks

● CP5 pallet (760 x 1140 mm) – small packages such as boxes and bins

● CP6 pallet (1200 x 1000 mm) – sacks

● CP7 pallet (1300 x 1100 mm) – sacks

● CP8 pallet (1140 x 1140 mm) – container transportation

● CP9 pallet (1140 x 1140 mm) – containers, drums and bulk bags

The importance of pallet quality

The chemical industry is particularly sensitive to industrial hazards, a fact that underscores the importance of pallet quality. “Storing and transporting packaged and bulk chemicals is both a high risk and complex process,” one industry expert wrote recently. “Complex because the sector is highly regulated and there are many raw materials and manufactured products that need to be handled in specific and unique ways. Products are high risk because they can be corrosive, volatile, hazardous and expensive to store and move.”

Given the risk of handling chemicals and their value, it is no surprise that the chemical supply chain often leans towards new pallets. “When you have an extremely valuable and sensitive product, why would you take the risk on a used pallet,” one former CP pallet buyer from Germany told Nature’s Packaging.

A quick online search indicates that both used as well as new CP pallets can be sourced in the North American marketplace. When customers specify a particular pallet, such as a CP pallet, it may be important to drill a little deeper to determine the sensitivity of customers regarding pallet certification and state of repair.

It is good practice to understand whether the customer requires a certified CP pallet as opposed to a non-certified pallet that broadly follows the specification. In a similar vein, used, certified pallets are often required to be in top condition due to the inherent risks of the supply chain.

It pays to take the time to fully understand customer pallet requirements. Watch for CP pallets to play an increasingly important role in the global chemical supply chain.