Wood Moves the World – Wood Packaging in Outer Space

Have you ever looked up into the sky and wondered, “Pallets are cool and all, but do they use wood packaging in space”? You are not alone! In this Nature’s Packaging post, we’ll go where no wood package has gone before and discover how wood will soon be launched into space through a collaboration between Arctic Astronautics Ltd., UPM Plywood, European Space Agency, and Huld Design.

First, let’s take a quick look at other space-based projects where wood has played a role. Starting in the early 1970’s and into the 21st century, China experimented with white oak tiles as an ablative shield on their FSW series satellites. This proved effective as the white oak tiles would heat and turn to char which acted as a protective layer during re-entry through the earth’s atmosphere.

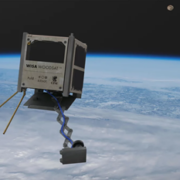

The WISA® Wood Cube Satellite (WoodSat for short) is a first of its kind nanosatellite that utilizes plywood as part of its structure. A nanosatellite typically weighs less than 22 lbs. and has a cube dimension of 10cmx10cmx10cm. They are designed for versatility and low cost. This gives researchers the ability to launch the satellite into space as part of a larger payload or into the atmosphere via high-altitude weather balloon.

“The mission of the satellite is to test the applicability of wooden materials, especially WISA-Birch plywood, in spacecraft structures and expose it to extreme space conditions, such as heat, cold, vacuum and radiation, for an extended period of time.”-UPM

The WISA® WoodSat is based on a Kitsat model available from Arctic Astronautics. The Kitsat is a fully functioning replica satellite designed for educational use and space hobbyists. You can buy a Kitsat with accessories and spare parts for ~$2,000 US dollars.

The WISA® plywood used for the real satellite is provided by UPM. UPM is a European company that focuses on providing recyclable products made from renewable resources. The plywood itself is a common birch base that was hand selected for this project, specially coated with an industrial UV lacquer, and dried in a thermal vacuum. All designed to protect the small satellite against UV radiation in space. Here’s a great video of the process.

The ESA or European Space Agency are interested in the project for testing the future use of wood in space-based platforms. They will provide the sensor suite and electronics that monitor the environmental conditions and integrity of WoodSat while deployed in space.

Huld (which is a combination of the words Humane and Bold) is a European technology design house that has been working in the space industry since the late 1980’s. For the WoodSat project, it is manufacturing the uniquely engineered deployable camera boom and the aluminum launch rails for the mission. Yes, the WoodSat will have a selfie stick for video and pictures.

The mission has progressed on schedule and on Saturday June 12th 2021, the first test flight of WISA WoodSat took place. Attached to a weather balloon, it went to approximately 19 miles (30 km) above Earth’s surface and into the stratosphere. The flight lasted for 2 hours and 54 minutes. The balloon exploded at altitude as planned and the test WoodSat deployed a parachute and floated back to Earth. During the flight, tests of its communication capabilities, command response, and selfie stick camera all passed.

Since the test model launched and worked as planned during the flight, the preparations for actual space flight to happen in the final quarter of 2021 will continue according to schedule. The flight model of WISA® WoodSat satellite and its spare were completed by the end of June. The spare model has been put into a space simulator and subject to extensive tests for vibrations that simulate a rocket launch and trajectory.

Innovative designs that utilize wood are a part of why wood wins. The WISA® WoodSat project is further proof that wood is a truly versatile material and wood packaging can go anywhere, including outer space.