2 Types of Recycled Pallets for Export

2 Types of Recycled Pallets for Export

The sustainable standards of ISPM 15 regulations apply to recycled wood pallets and prevent them from spreading wood boring insects across international borders. These standards help ensure recycled wood pallet and crate companies do their part to protect the environment. ISPM 15 separated recycled pallets into two categories: repaired and remanufactured.

It’s Like Buying a Used Car

When a pallet company buys broken, heat treated, recycled pallets from their customer, most of the pallets require some repair. The pallet company brings the recycled pallets to their facility to sort through them. They fix the repairable pallets and salvage the others for parts.

Buying used pallets is like buying a used car. You could buy a reliable used car that might have had the transmission, radiator, or other parts replaced and it will still be safe and effective to drive. It’s the same car it always has been; it’s simply had a part or two replaced. In the same way, replacing the bad parts of a pallet extends the life of the pallet. ISPM 15 has two categories for recycled pallets. The first category is repaired pallets, referred to in section 4.3.2 of ISPM 15.

Repaired pallets have had up to one-third of the components replaced. This is like the new car that had its radiator replaced. Everything is still new except for that one part. However, once a pallet reaches the end of its life, it’s dismantled and the usable boards are stacked and separated for re-use on other pallets. The unusable boards are recycled into products like wood chips or sawdust for different industries.

It’s possible to make a pallet entirely from recycled boards. If a pallet has had more than one-third of its boards replaced, then ISPM 15 considers it remanufactured, referred to in section 4.3.3 of ISPM 15. This is like the car that has had its engine, transmission, and radiator replaced with parts (new or used) all sourced from different places. When a remanufactured pallet has been repaired with lumber sourced from different locations, separate rules apply. Processes need to be followed to ensure that pallet is ISPM 15 compliant and won’t spread wood-boring pests from one country to another.

Stamping for Export

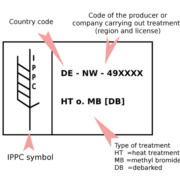

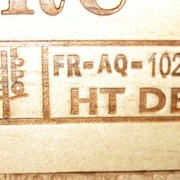

The governing agency for each ISPM 15 participating country distributes a unique number to be assigned to a stamp. Each company that participates in the ISPM 15 program must clearly stamp each heat treated wood product that leaves their facility with their number. That way, the source of each wood product can be traced in case there’s a problem. Depending on the pallet’s origin, a used pallet can sometimes have more than one stamp on it to certify heat treatment. In the United States, it’s required that all previous stamps be obliterated before a pallet is heat treated. Only then can a new stamp be applied.

The language of ISPM 15 is used as a minimum requirement for all countries that participate. The agency that oversees ISPM 15 in each country has the authority to include additional standards. Put differently, the rules that apply to businesses in Canada are different than the rules that apply to businesses in the United States. The agency that oversees the Canadian ISPM 15 program is the Canadian Food Inspection Agency. In the United States, it’s the American Lumber Standards Committee. Refer to links below for more information.