Nature’s Packaging-Let’s Learn About Sawmills

Sawmills remain one of the most important tools for the creation of wood planks, taking raw timber materials and turning them into usable wood. The sawmill’s basic operation has not changed much since its creation. In this Nature’s Packaging post, we’ll learn how sawmills operate and their history.

What is a Sawmill?

In a modern mill facility, the raw timber can be debarked and bucked (cut to length) before entering the mill or those processes can be part of the intake process of the mill itself.

The next phase of the process is converting the logs into boards with the use of several motorized saws at various stages that start by cutting large timbers into several smaller rough sawn pieces. Those rough sawn pieces can then be “re-sawn”, which is when the wood is finished into boards of various thickness and lengths, and can also be planed for smoothness.

This is a quick general overview of processes and methods in a mill, there are many different specialty operations that can also take place in a sawmill and those will be covered in other Nature’s Packaging posts.

The History of the Sawmill

Prior to the use of sawmills, boards were cut manually using saws operated by men. The wood was rived and planed and then hewn.

Pitsaw operation

Typically, two men used a whipsaw or pitsaw to do this, one above and one person under it in a saw pit. The whipsaw, a long blade held on either side, was moved back and forth to cut the wood to just the right level.

There is evidence of mechanical sawmills that date back to the 3rd century AD.

Roman Hierapolis stone sawmill-3rd century AD

In the 11th century, the use of water-powered mills helped to ease the burden while producing more of the materials people needed as cities and towns grew. These water-powered systems were common in Spain, the Middle East, Central Asia, and Northern Africa. A few hundred years later, they were widely present throughout Europe.

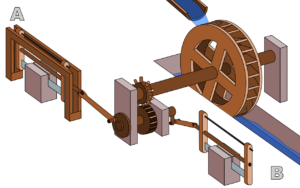

Water wheel mill

In this version of a sawmill, a circular motion of the wheel helped to create the movement of the blade. Only the saw had power derived from the water, and the logs were typically still loaded by hand. A movable carriage eventually developed to speed this up.

In the 18th century, the Industrial Revolution created significant change for the timber industry. A circular saw blade was invented during this time, with credit going to Samuel Miller via a British patent #1152 in 1777.

The use of steam power in sawmill operations a century later meant that sawmills could operate at a faster rate to keep up with the ever-growing demand. The scrap lumber from the mill was often used to maintain a boiler.

In the 20th century, electricity was introduced and revitalized the way sawmills worked again. By adding electrical power and more innovation through computer technology, sawmills can produce lumber at a very fast rate by maximizing the number of optimal cuts taken in a single log.

How Today’s Sawmills Work

The same basic methods are still used in sawmills today though today’s mills are far more massive in size and capable of producing a large amount of lumber very quickly. They are expensive to run as most are highly computerized to make use of as much material as possible while still working to be efficient.

The process works as follows:

- Trees are selected for harvesting, the trees of felled, and they are bucked to length, meaning just the logs are taken to the mill to be used.

- The branches are removed in a process called limiting. The logs are loaded onto a truck and driven to a railroad or other location nearby for transportation.

- The logs are scaled and debarked as the first steps. Then, the logs are sorted by species, size, and the end use for them, such as chips, plywood, or lumber.

- The logs are then sized down to be able to be placed into the sawmill based on the desired end goal.

- The cants (or unfinished logs) will then be broken down further. The fitches, which are unfinished planks, are then edged to remove any irregularities.

- The finished pieces are trimmed, dried to remove moisture, planed to smooth the surface of them, and then shipped to their destination.

The Rise of Portable Sawmills

Portable sawmill

Portable sawmills have existed for over 100 years, but they gained real popularity in the 1970’s. These portable sawmill operations helped meet the exploding need for lumber products in the construction and forest products industries.

Because these portable systems can process material that would otherwise be wasted or underutilized, they are a unique solution for today’s industry and able to help reduce carbon emissions by processing materials onsite.

Portable thin kerf bandsaw mills are relatively easy to operate and can produce high-quality finished lumber from just about any species of tree. Initially, many property owners purchased portal lumber mills so they could clear a stand of trees quickly. They found that lumber was a profitable business, which encouraged them to expand their operations.

Today, portable mills are effective at not just producing quality finished products, they are also reducing the environmental impact of lumber production. A portable sawmill can harvest smaller sections within a stand of trees, and they lower the need to transport logs to another facility for processing, thereby removing steps from the process.

Portable sawmills can be helpful in urban areas. Trees that pose a public safety risk to pedestrians or that normally wouldn’t be processed in an urban environment can be removed and made into boards and other usable materials.

Portable sawmills can help foster more forest stewardship through more precise forest management and lessening the environmental impact of harvesting activities.