ISPM 15 and Sustainability

History of ISPM 15

The International Stands for Phytosanitary Measures No. 15, referred to in the industry as ISPM 15, is an International Phytosanitary Measure developed by the International Plant Protection Convention (IPPC). According to its documentation, the primary goal is to “reduce the risk of introduction and spread of quarantine pests associated with the movement in international trade of wood packaging material made from raw wood.” The language is comprehensive, covering all forms of wood packaging that serve as pathways for pests that could pose a risk to living trees.

The IPPC is a multilateral treaty signed into effect on December 6, 1951. As of 2010, 74 countries participate in the program. According to the IPPC, the “ISPMs provide globally harmonized guidance for countries to minimize pest risk without creating unjustified barriers to trade, ultimately facilitating their exports and imports of plants and plant products.”

How Wood Packaging Companies Comply

In North America, if a wood products company wants to export lumber then they must comply with the program. The most common way for companies to comply with ISPM 15 standards is by heat treating lumber. In order for lumber to meet these standards, the internal temperature of the timber must reach 56 degrees Celsius or 132.8 degrees Fahrenheit for 30 minutes in a kiln. Certain types of lumber, such as plywood, oriented-strand board (OSB), and sawdust are exempt from these standards as they are exposed to the heat-treating requirements during the manufacturing process. The purpose of heat treating lumber to meet ISPM 15 standards is to reduce the risk of spreading wood boring insects.

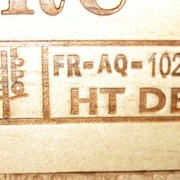

Wood packaging companies that participate in the ISPM 15 program are assigned a stamp with a unique number and that stamp must be clearly applied to all products used in export. They must keep written logs of incoming heat treated lumber and any outgoing orders where the stamp was used. Compliance is monitored and enforced by third party companies that make unscheduled monthly visits to the wood products companies to ensure all rules and regulations are followed. Some of the largest North American inspection companies are Timber Products, Pacific Lumber Inspection Bureau, and West Coast Lumber Inspection Bureau and they work closely with the United States and Canadian governments. If a wood product company doesn’t follow the rules of the program, they can get their stamp revoked and they won’t be allowed to certify lumber products for export.

ISPM 15 and Sustainability

Lumber and other wood packaging companies across North America have widely adopted the ISPM 15 standards and these standards are intended to help protect our forests from wood-boring pests. According to ISPM 15 language, “Pests associated with wood packaging material are known to have negative impacts on forest health and biodiversity. Implementation of this standard is considered to reduce significantly the spread of pests and subsequently their negative impacts.” By adopting ISPM-15 protocols into the manufacturing processes and by achieving the high levels of industry compliance, the wood packaging industry will enhance its role as stewards of the resource, reducing the risk of spreading wood-boring insects which results in elevating the sustainability of the products we produce.